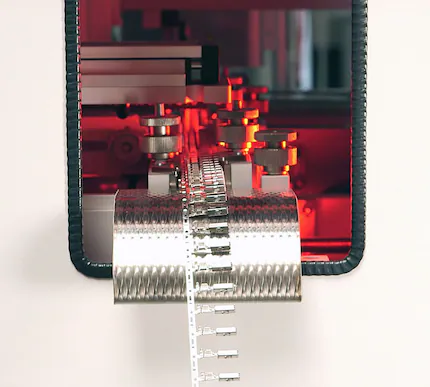

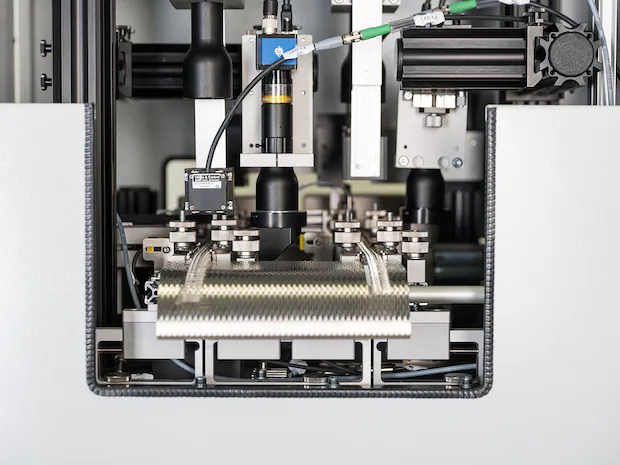

High-Performance In-Line Camera “Inspection” Grade System – COMPACT

- Compact and space-saving design

- Usually use of 2 – 3 cameras

- Plate can be exchanged to the front

- Control unit direction-dependent

- Description

Description

Revolutionizing Stamped Part Production with Cutting-Edge Optical Inspection Systems

Our advanced industrial optical 2D & 3D systems stand as the ultimate solution for those who demand absolute precision in inspection standards in their In-Line Stamping or Plating Operations.

These machines elevate the inspection process to the standards of a quality department, bringing real-time monitoring of production quality to your fingertips, even from a remote location.

As the demands for efficiency and cost-effectiveness in stamped part production surge, manufacturers are in need of competitive solutions that ensure zero-defect production. With increasing process complexity, customers now expect meticulous quality control—every part produced must be measured, checked, and recorded.

Enter our innovative inspection stations, a quantum leap from traditional random inspections by the quality department. We offer a fully automated in-line solution that integrates inspection, measurement, and sorting of stamped production parts.

The real-time delivery and processing of inspection data, starting from the first punching stroke, streamline changeover processes, boost stamping utilization, and minimize resource consumption. For our customers, this translates to enhanced quality at reduced costs.

Performance Guaranteed…

Our systems go beyond expectations, inspection parts with over 180 dimensions at an impressive rate of 1800 strokes per minute.