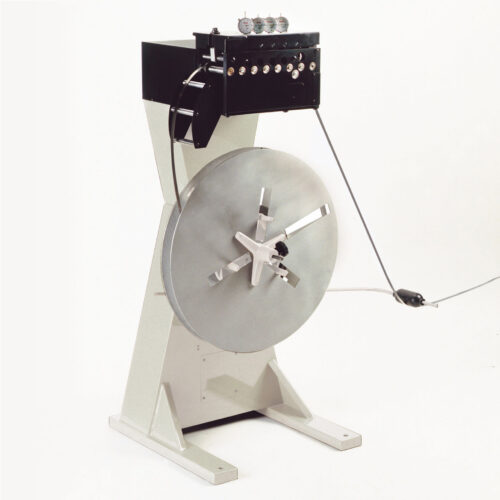

Smoothly deliver material to automatic feeding equipment with industry-leading decoiling equipment from BRUDERER UK. All of our wire decoiler machines are precision-engineered to deliver reliability and precision built from decades of experience and quality craftsmanship. With a straightforward set up, our decoiling machines are fully adjustable to your specific requirements, whatever your industry. Incorporating the latest in control technology, we work to the highest levels of consistency and accuracy to ensure we meet today’s quality demands. Our decoiler machine range includes drum and pallet decoilers, horizontal and vertical fixes shaft pay-off decoilers and light, medium and heavy-duty decoilers. Based on our experience, we also supply individual machines such as straighteners, feeders, shearing units, designed and installed as per your specific requirements. For more information about our steel and wire decoiler machines, contact our UK-based technical sales team for more information.

MENUMENU

- Presses

-

-

-

Perfect Match.

Your BRUDERER Stamping press can do so much more

Limitless scope of application, utmost precision.

Stamping Presses Finder

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-

-

- Ancillary Equipment

-

-

Perfect Match.

Your BRUDERER Stamping press can do so much more

Limitless scope of application, utmost precision.

Stamping Presses Finder

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-

- Tooling

- Services

- PREOWNED MACHINERYBruderer UK Ltd has a wide range of pre-owned machinery, our pre-owned presses in stock at our Luton works, with tonnage capacities ranging from 20ton to 60 ton and also a range of used press shop accessories. All pre-owned presses supplied by Bruderer UK are selected from know sources so that the quality of the press can be guranteeed. Every press is subjected to a full and thorough inspection; all apspects of the presses are tested and reworked to ensure they meet the original specifications set-out by the manufacturer. We are also able to offer complete machine refurbishment and overhauls to meet customers individual and exact requirements.

- Contact

-

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-