HIGH PRECISION TOOLING SOLUTIONS

BRUDERER stands as the global leader in High Precision Presses and our commitment extends beyond just the machinery, we actively collaborate with our customers to support them in fully optimising all elements of the process including tooling!

Our UK Technical Sales Team, comprised of seasoned toolmakers with a broad spectrum of expertise. This unique position allows us to draw upon a vast reservoir of experiences and past projects.

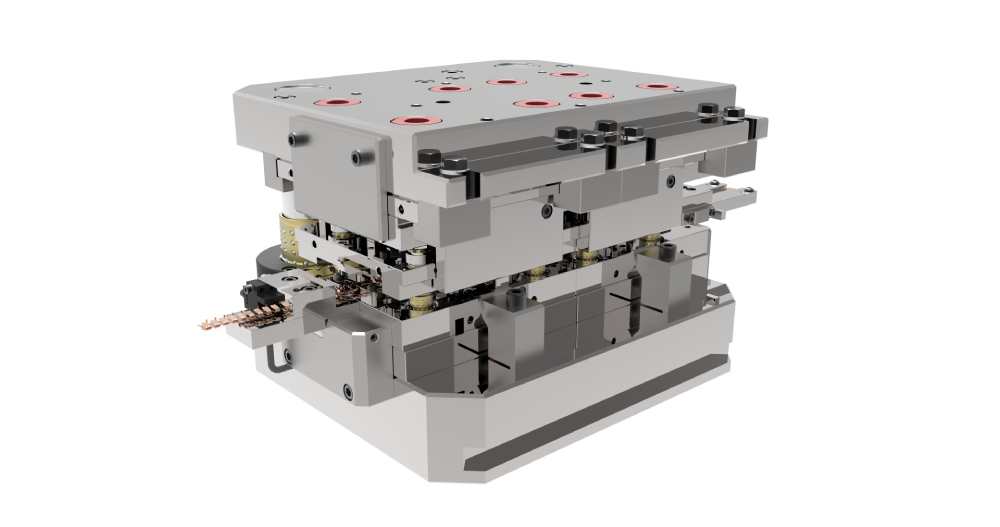

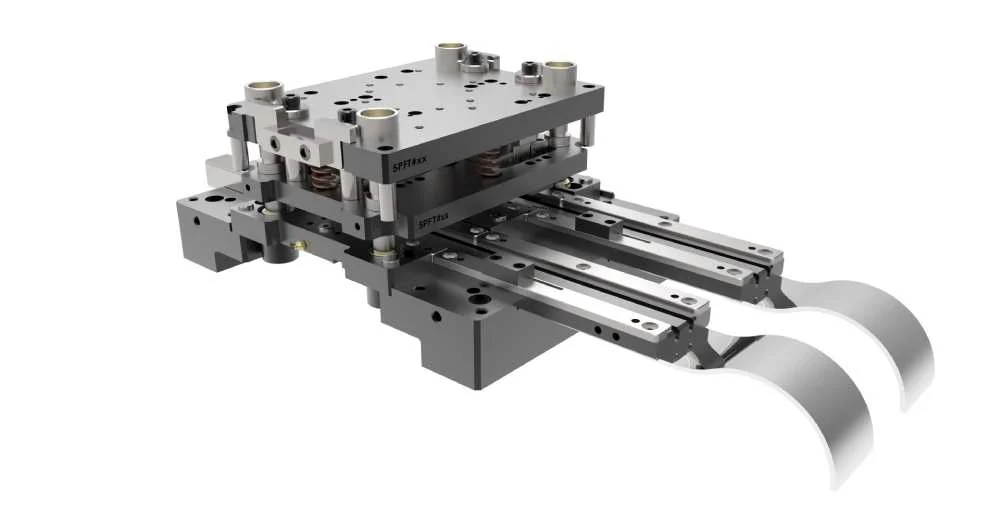

Allowing us to offer tooling solutions for High Precision Modular Progression Tooling, High-Speed Premium Tooling, Traditional Progression Tooling, High-Tonnage Servo Press Tooling, Lamination Tooling including In-Die Stacking & Rotation, Transfer Tooling, Deep Draw Tooling, Battery Tooling and Canning Tooling.

We also offer Specialised Tooling for Multi-Slide Machines (Finzer, Biegema & Similar) in the addition to tooling for Platarg / Invernizzi Multiple Ram Transfer Machines and Special Purpose Automation Tooling.

We seamlessly bridge the gap between tooling and machinery.

This distinctive capability ensures the delivery of the absolute best solutions for you and your business.

Whether you need a new tool for a product, a suite of tools for a product range, resolution of problematic issues with current tooling – we are here to support.

Customers also engage us for R&D processes not only with product development but also process development R&D, where we help push the boundaries of production speed, part quality, tool-life, consistency, efficiency and much more…

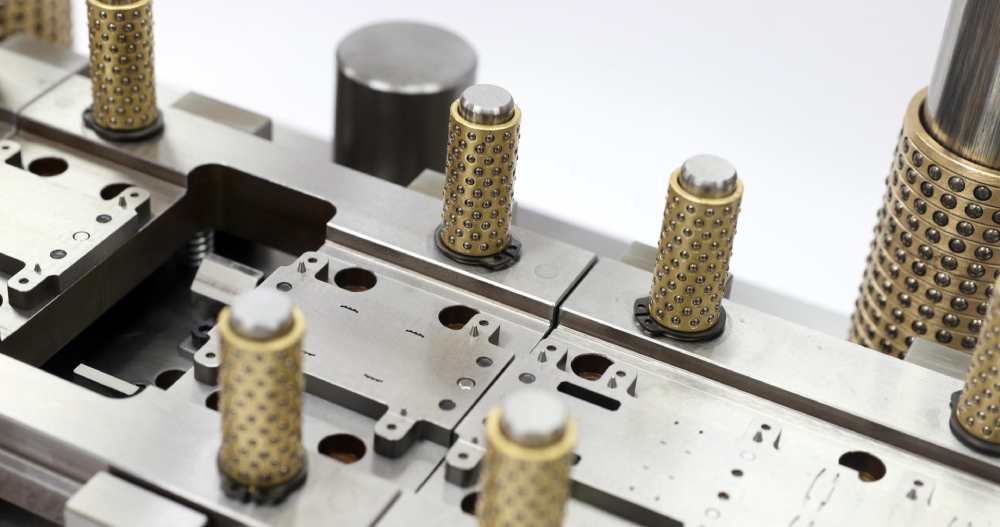

We have at our disposal the latest in Presses, Machining Centres, Grinding, EDM and Wiring Solutions, along with collaborations with Toolroom Machinery OEMs to push the limits.

Subject to requirement we can implement a complete NPI process through gated structure that ensures all information, tasks, roles and responsibility are clear, defined and captured and completed before progress to next gate.

Long-standing relations with many standard tooling part suppliers allow us to work with your current supply chain and if so required pull from others if we recommend so you have the very best solution.

Complete TPM (Tool Preventative Maintenance) and after-sales supply chain support structure will be implemented upon completion of project.

We excel in integrating and utilising In-Die Automation, whether that be moving customers from Pneumatic Tool Actuators (Tool Gags) to Fully Controllable Electronic Actuators Solutions, eliminating secondary welding processes with the implementation of In-Die Welding Solutions like Laser or Resistance welding, Wire Riveting, Solderless Connections, Thread Forming and In-Die Part Transfer Systems.

We also have experience in delivering twin-track solutions for high-output lines.

During the review process we evaluate the application and ensure correct sensing and process control is equips, be that simple sensors, advanced in-die tonnage sensors or full 100% part inspection camera solutions with automatic feedback control to servo axis actuators to crop part out be that in-die or external.

We look forward to hearing about your next challenging project!