BRUDERER UK Highlights Innovation and Excellence at Blechexpo 2025

The BRUDERER UK team was delighted to join our global colleagues at Blechexpo 2025 in Stuttgart last week, held from October 21–24. This year’s exhibition was a fantastic opportunity to connect with industry partners and showcase two major technological advancements: the B3 machine control system and the BSP lamination stacking control—both designed to elevate stamping automation to new heights.

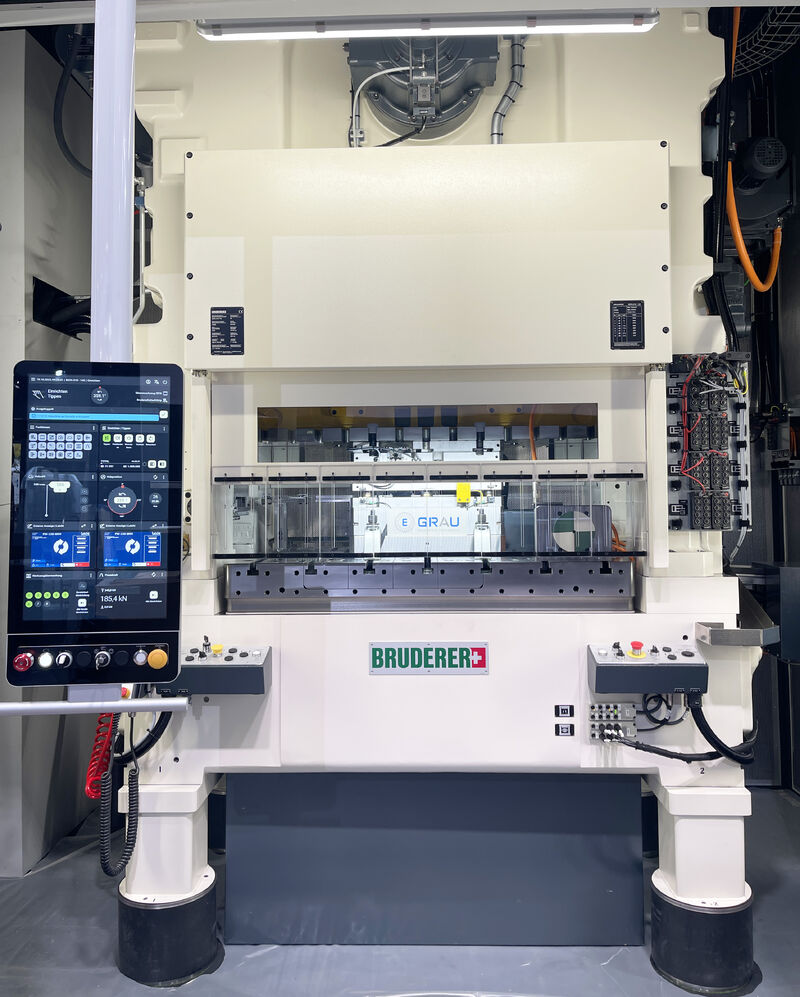

At our stand in Hall 6, Stand 6309, visitors experienced these innovations in action on a fully operational stamping line. The setup featured our BSTA 810 high-speed stamping press, paired with a BSV servo feeder and a precision tool supplied by our trusted partner, Erich Grau GmbH. The live demonstrations drew strong interest and highlighted the performance and integration capabilities of our latest solutions.

B3 Machine Control – Designed for the Future of Stamping

The B3 control system is a completely reimagined platform, developed from the ground up using insights from over 5,000 B and B2 installations worldwide. It offers a modern, intuitive interface with a 21-inch touchscreen and tile-based layout, making it easy to navigate and reducing the learning curve for operators. Enhanced security through role-based access and full integration with third-party peripherals ensures flexibility and control.

Built with scalability in mind, the B3 system supports everything from basic stamping tasks to highly complex operations. New features include automated setup and monitoring of tools, sliders, and indexing stations, all made possible through intelligent parameterisation—streamlining changeovers and improving process reliability.

Enhanced Connectivity and Process Control

The B3’s main interface provides real-time control over press force, tool position, and system diagnostics. Advanced envelope monitoring enables early fault detection, while OPC-UA connectivity ensures seamless integration with production control systems and Industry 4.0 environments. The B3 will be standard on all new BSTA presses from 2026, with retrofit options available for existing machines from mid-2026.

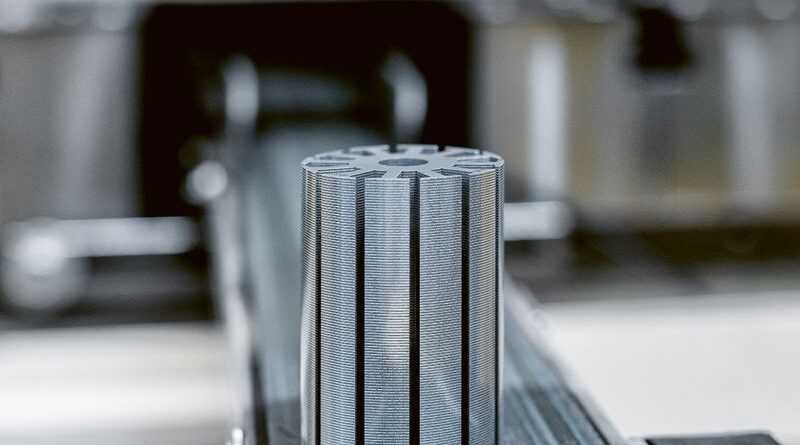

BSP Lamination Stacking Control – Precision for Rotor-Stator Production

Also unveiled at Blechexpo was the BSP lamination stacking control, a powerful solution tailored for the growing demands of electric motor and transformer component manufacturing. Built on the B3 platform, BSP enables complex stacking strategies with up to eight programmable channels, all managed through a user-friendly interface.

The system supports plug-and-play configuration of up to six indexing stations, with automatic detection and setup of motors, sliders, and tool monitors. This dramatically reduces setup time and minimises the risk of human error, making it ideal for high-precision rotor-stator production.

Intelligent Monitoring and Consistent Quality

The BSP system includes a patented strip measurement and stack height control feature, capable of detecting and compensating for material variations as small as ±0.01 mm. This ensures consistent product quality and dimensional accuracy, even in high-volume production environments. BSP is available either as a fully integrated module within the B3 system or as a stand-alone solution, offering flexibility for a wide range of applications.