MENUMENU

- Presses

-

-

-

Perfect Match.

Your BRUDERER Stamping press can do so much more

Limitless scope of application, utmost precision.

Stamping Presses Finder

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-

-

- Ancillary Equipment

-

-

Perfect Match.

Your BRUDERER Stamping press can do so much more

Limitless scope of application, utmost precision.

Stamping Presses Finder

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-

- Tooling

- Services

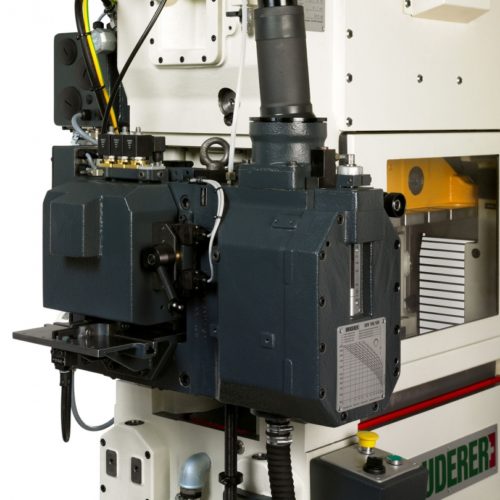

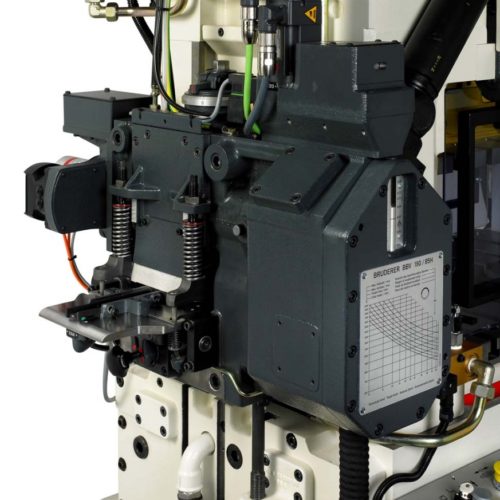

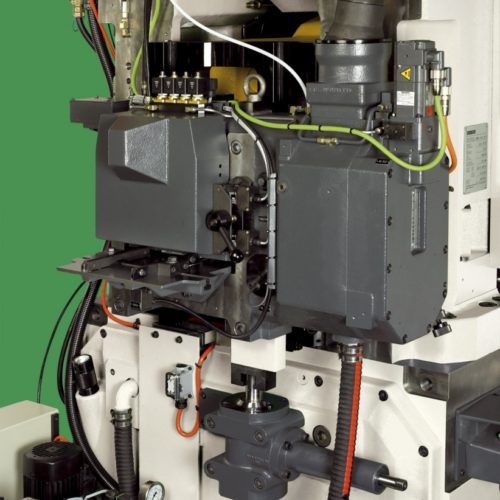

- PREOWNED MACHINERYBruderer UK Ltd has a wide range of pre-owned machinery, our pre-owned presses in stock at our Luton works, with tonnage capacities ranging from 20ton to 60 ton and also a range of used press shop accessories. All pre-owned presses supplied by Bruderer UK are selected from know sources so that the quality of the press can be guranteeed. Every press is subjected to a full and thorough inspection; all apspects of the presses are tested and reworked to ensure they meet the original specifications set-out by the manufacturer. We are also able to offer complete machine refurbishment and overhauls to meet customers individual and exact requirements.

- Contact

-

-

-

BRUDERER UK LTD

CRADOCK ROAD, LUTON,

BEDFORDSHIRE,

LU4 0JF

UNITED KINGDOM

-