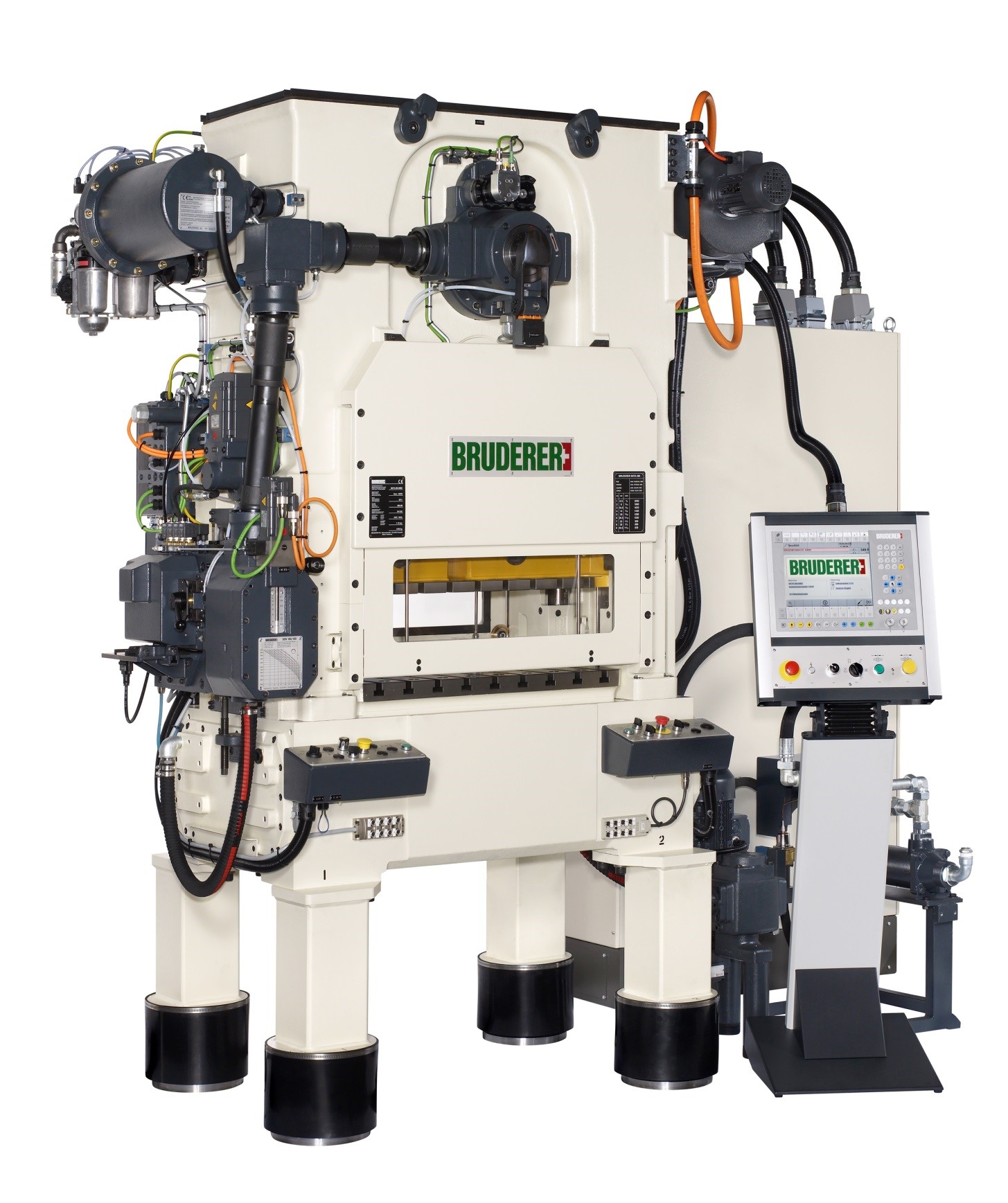

Introducing the BRUDERER BSTA 280

Advantage through Innovation and Technique.

The BRUDERER high performance stamping press BSTA 280, combines brilliant precision mechanics, modern electronics and trend-setting innovations. Its unique cost-benefit ratio sets new standards in the market. The drive mechanism of the BSTA 280 embodies traditional BRUDERER technology in its most advanced form. The heart of the machine is the short and rigid main shaft that is mounted in transverse direction.

The power transmission through connecting rods and the unique lever system in combination with the perfected mass counterbalancing system guarantees unsurpassed life time and perfect precision. The hardened and ground spindles of the ram height adjustment are mounted outside the power flow and hence allow a precise setting of the ram during the punching process. As the mechanism does not generate lateral forces being transmitted into the ram guides, the guides are placed exclusively in the strip level which prevents deflection of the punches due to eccentric loads in the die.

The above facts result in a safe and cost-effective stamping process.

BSTA 280

High performance stamping press with perfected mass balancing system and adjustable stroke.

Press force 280 kN & speeds ranging from 100 to 2000 spm.

Modular design, bolster plate dimensions:

– BSTA 280-75 740 x 536 mm

– BSTA 280-88 870 x 536 mm

Press control on PC-basis, touch screen with clearly arranged graphics for easy handling, memory function for die parameters and integration of measuring and control function for increased process safety.

Precision mechanics, versatile – can be used for a number of different applications, optimum cost-benefit ratio.