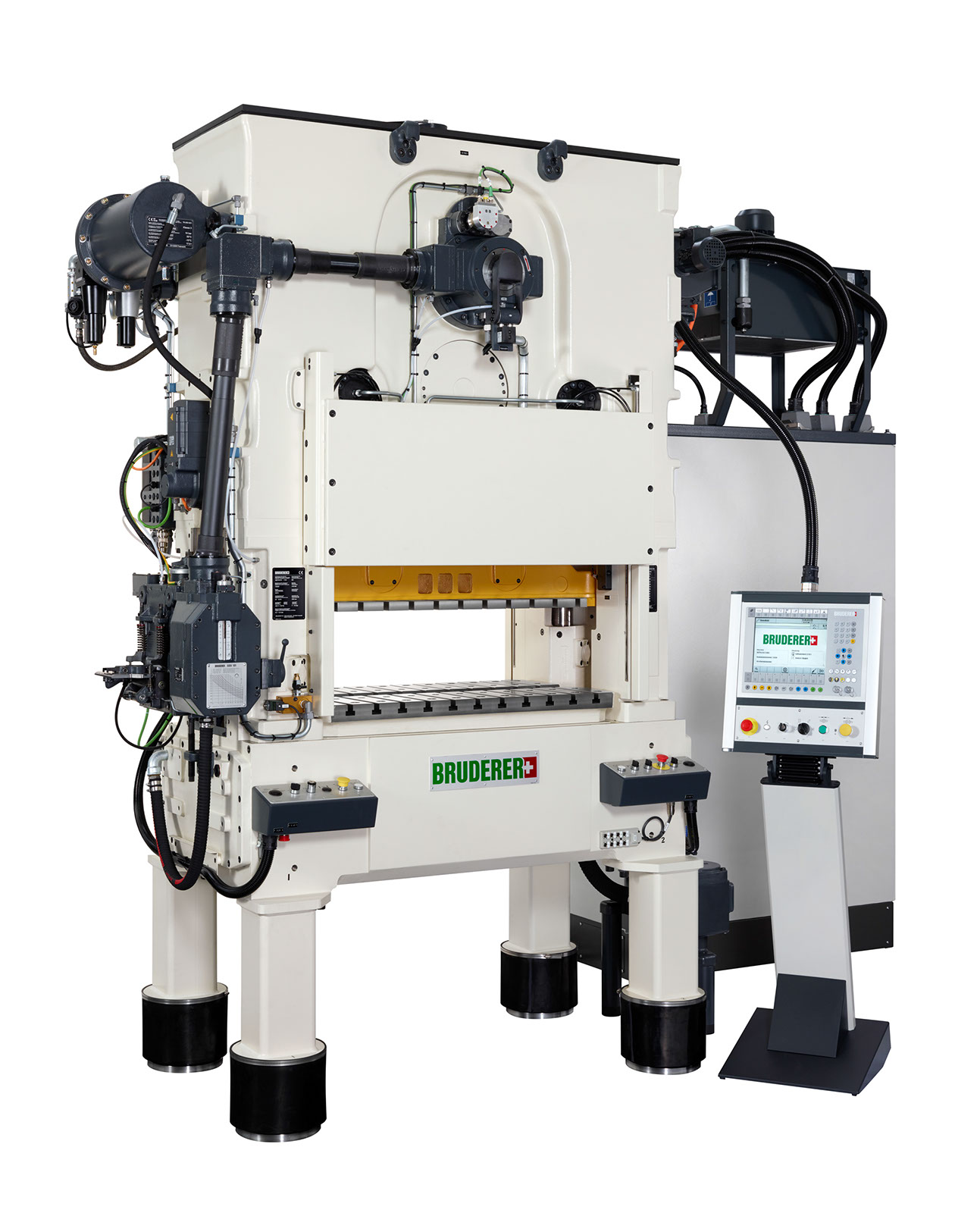

BRUDERER unveils the BPG-22 Planetary Gearbox

BPG 22: A fully-automated stamping press and test press all rolled into one

The BPG 22 planetary gearbox developed by BRUDERER is a world first, and something that stamping experts and tool-makers have been waiting for – for a long time. It is an additional gearbox which will enable fully-automated BRUDERER BSTA 510 stamping presses to be turned into test machines for trying out new tools at the flick of a switch, and then afterwards return to serial production – creating incredible added value for BRUDERER customers!

In the past, stamping firms who created tools in-house had only one solution for these two very different tasks – they had stamping presses for actual production whilst having to carry out tool and stamping tests on a separate machine, which would then as a rule stand idle until the next series of tests, taking up valuable capital and production space.

Two becomes one

This new development from BRUDERER now offers a practical alternative which provides the customer with real added value. A planetary gearbox that is built into the shaft of the main motor of a fully-automated stamping press enables test runs to be carried out, steered by manual control, at the lowest stroke rate and at full press capacity. The values that are produced can then be carried over exactly and used in the regular production process. The advantages for customers are manifold: increased efficiency, reduced costs, less space required, simple handling and more flexible work processes. There is also a gain in terms of logistics, since tools have to be transported less often.

The catalyst for this development was the servo technology which has become far more prevalent in recent years. While it is of little or no use for stamping at high stroke rates, which is one of BRUDERER’s core competencies, it is however very suitable for slower processes such as test stamping and try-out of tools. BRUDERER therefore decided to use these very properties and adapt them to their high-performance fully-automated stamping presses, and the result is the BPG 22. The aim was to combine two machines in one – namely to take a regular high-performance fully-automated stamping press and equip it at very low stroke rates with the capabilities of a test press, which however do not have any influence on the (day-to-day) functioning at higher stroke rates. A particular challenge was making the strength and torque which are required for comprehensive test settings available without the need for a significantly larger electric motor or having to changing something significant to the basic principles of the tried and trusted BRUDERER stamping press.

All different, all new

The project team found themselves confronted with quite a task. It was not merely a case of developing a planetary gearbox – it had to be a three-level version. The basic concept also called for it to be enclosed in a rotating casing, which posed a further challenge. For project manager Pascal Hardmeier and the rest of his team, there was a lot to learn, and while that did not make for an easy time of things, it was certainly exciting and enriching work.

After the gearbox had been constructed mechanically, it was time to focus on the development of the software, and this proved to be an exciting challenge for Herbert Högger, Head of Control Engineering, and Sven Kächelin, in charge of the relevant software development. This was a project where production at low speed was the main priority as opposed to stamping, and this meant that everyone involved had to approach the project from a completely different point of view. The work on the BPG 22 also provided new insights of a more general nature, for example in terms of process monitoring or the behaviour of BRUDERER fully-automated stamping presses at low stroke rates. What Herbert Högger found most impressive is the fact that the complete tonnage of the machine is literally in the hands of the machine operator. Kächelin found the development of the manual control particularly demanding. The requirement was for it to be able to work slowly but at high strength and this ended up creating various new functionalities. BRUDERER and the relevant suppliers were also involved on the hardware side, and whereas »speed at all costs« used to be the watchword, now it is more a case of »slower but stronger«. Consequently everybody involved in the BPG 22 project has come to see the BRUDERER stamping press in a new, previously unseen light.

The result of this teamwork is a three-level planetary gearbox with a ratio of approximately 1:19. The real heart of the BPG 22 is the software and the manual control for the machine. The main functionalities include the switching on and off of the gearbox in test mode, movement of the machine and adjustment of the ram height all via manual control, as well as production at low stroke rates. The data that is generated can then be transferred to the tool data memory of the machine’s control system.

Everything in hand

The manual control enables the speed of the ram movement to be adjusted to different levels. Maximum press capacity and the highest torque levels can also be set and recorded. The machine operator can thus start the top and bottom dead centre individually and move the ram to precisions of a hundredth of a millimetre. The manual control can activate and control the functions that are required for test mode. This for example means that the ram and the upper part of the tool can be moved extremely slowly onto the lower part, imitating a stamping process and testing move slowly forwards or backwards in fixed geometrical increments or by regulated shifting using pre-set values. Backwards movement can be implemented depending on the tool, and the permitted press capacity can be changed where necessary. The operator can also specify breakoff criteria for continuation or return stroke in the control system.

The manual control has several different indications. A multi-coloured display shows the maximum and current press capacity, the press angle in degrees and the distance of the ram from the lower dead centre. The control also enables error messages from the machine to be displayed and acknowledged. It is linked to the machine by a pluggable cable and can be used in front of or behind the fully-automated stamping press, with the necessary cable connections built in on both sides. If the manual control is not required, it can be stored in the wall mounting that is delivered as standard or attached by means of a magnet to a place of the operator’s choice around the machine.

Functional and practical

Safety was always foremost in mind during the development of the BPG 22 since there are times when machine operators have to use their hands inside the tooling or stamping area when in test mode. The BPG 22 was thus constructed according to the European 2006/42/EG machinery guidelines, and is designed in such a way that test mode is automatically switched off if there is any kind of power outage. If the stamping press is then switched on again, it starts up in regular stamping mode. Test mode also needs to be able to be activated manually if required. The machine is constantly engaged when it is in test mode and the operator controls the stamping press manually. When it is switched off, the gearbox then goes into neutral and the machine is ready to resume its normal stamping functions.

The BPG 22 has no negative effects on the regular stamping process. On the BSTA 510 when it is in stamping mode, the usual stroke rates of between 100 and approximately 1100 strokes per minute, depending on the machine size, are still possible. The BPG 22 also has no effect on the footprint of the machine – the planetary gearbox is fitted in a way that the stamping press needs no extra floor space to accommodate it, which is another advantage compared with previous solutions which required separate equipment for test and production functions.

As far as company owner Adrian Bruderer and CEO Andreas Fischer are concerned, the BPG 22 which is not only a world first but also an incredible idea, and they are sure that this extension of functionality will be a real success. The gearbox was developed in close cooperation with a number of key customers and will be commercialised with a software stand, with any further enhancements worked out with customers based on needs and practical experience.

The new 22 kW planetary gearbox is available for the BSTA 510 with three different die mounting lengths of 950, 1100 and 1250 millimetres and will be delivered exclusively with new machines. Other versions for the various different types of BSTA will also be developed, depending on market requirements.