Big Investment to Boost Turnover

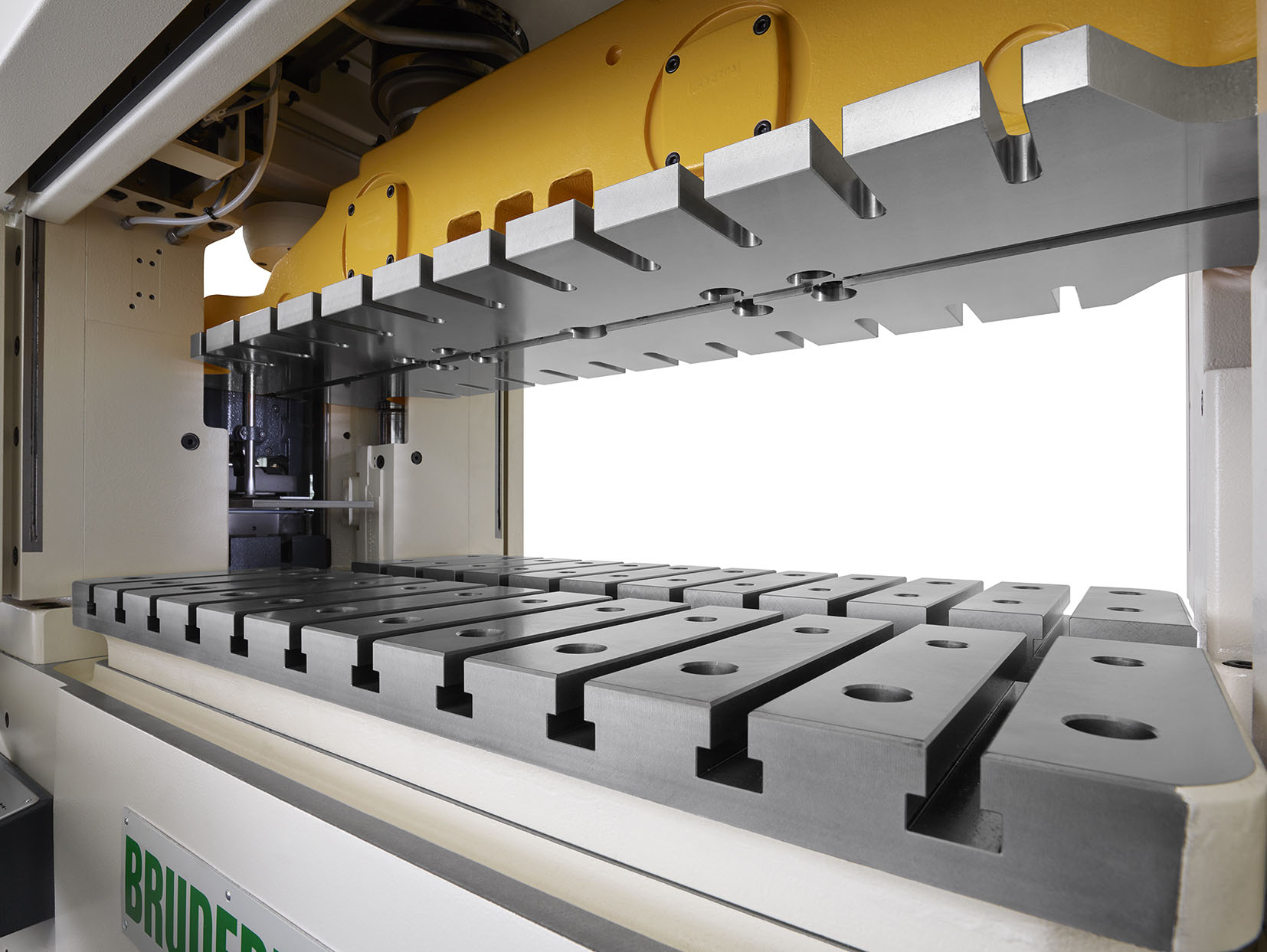

One of Birmingham’s longest established manufacturers is targeting a £10 million turnover after announcing major expansion plans. Brandauer – a world leader in precision pressings and stamping – is celebrating its 150th anniversary in 2012 by channeling £750,000 into two state-of-the-art Bruderer presses which will increase capacity, improve accuracy and open up a host of new markets.

It represents the largest single investment in the company’s history, with the new machines able to produce two billion parts every year – worth up to £2.5m in potential new sales. David Spears, managing director at Brandauer, believes this acquisition marks the next stage of its development: “2011 has started well and we’re winning new business in both existing and new markets, including exciting orders for complex and larger components for the medical and renewable sectors respectively.”

“Turnover has rocketed to over £9 million and we have reached a stage where we require additional capability in order to meet anticipated client demand.” He continued: “We identified the fact we needed machines that could give us greater speed, accuracy and a bigger tool die area that is able to deliver more added value at point of manufacture.”

Funded entirely through its own reserves, Brandauer tapped into its long-term relationship with Bruderer to purchase two machines. Both are high-speed fully automated power presses. One is so new the company will be among the first in the world to have it installed and operational.

David added: “This is a real show of intent and will illustrate to existing and new customers that we plan to offer them the very best level of service and manufacturing performance.

“This investment gives us greater speed, greater accuracy and greater efficiency to target new industry sectors.”

The two high speed precision stamping presses have been ordered and will be delivered to the firm’s Newtown facility by April 2012.

Adrian Haller, managing director of Bruderer UK, added: “At £750,000, this is the largest order we have secured in our history and is a further indication that UK manufacturing is committed to being the best in the world.”