High Accuracy Press & Tool Monitoring Systems for STAMPING PROCESSES

GENERAL SPECIFICATION, SUBJECT TO CHANGED BASED UPON CONFIGURATION

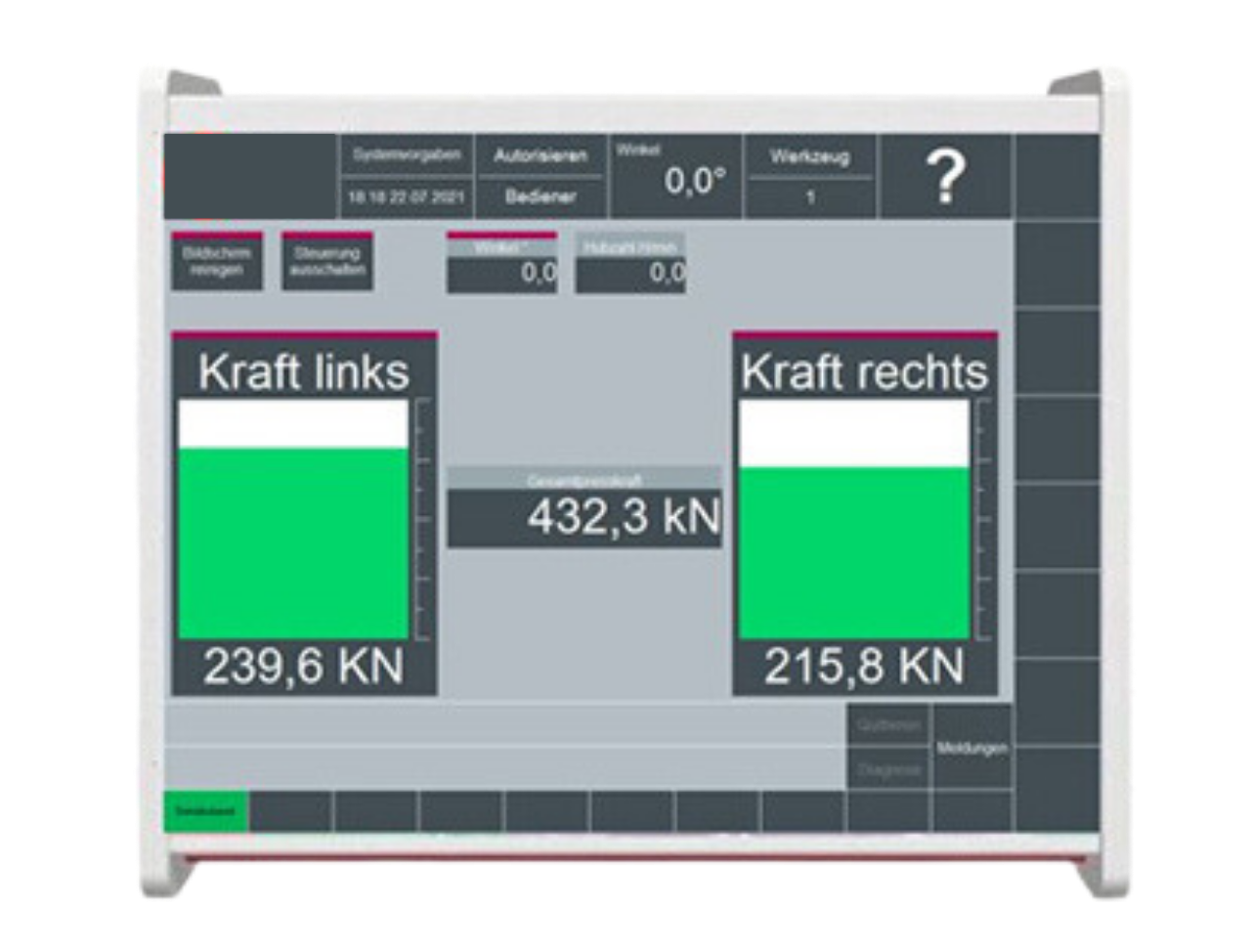

Press Force Load: 2x or 4x Load Channels

Up to 12x Separate Analogue Tool Channels i.e. PSA Sensors

Up to 24x Digital Inputs / CAM Outputs *Special Large Sensor Qty’s Available*

Tool Library Up to 1000 Tools; Including Die Number, Parameters, Note Pad and Various other Tool Specific Options…

Dynamic Envelope Curve Monitor at Standard

Interpretable into any press machine tool or similar process.

- Description

Description

In the realm of press and stamping processes, our highly accurate press and tool protection systems assume a pivotal role. Integral to any press-shop and quality accuracy strategy, these systems are meticulously designed to safeguard not just the machinery but the invaluable tools themselves.

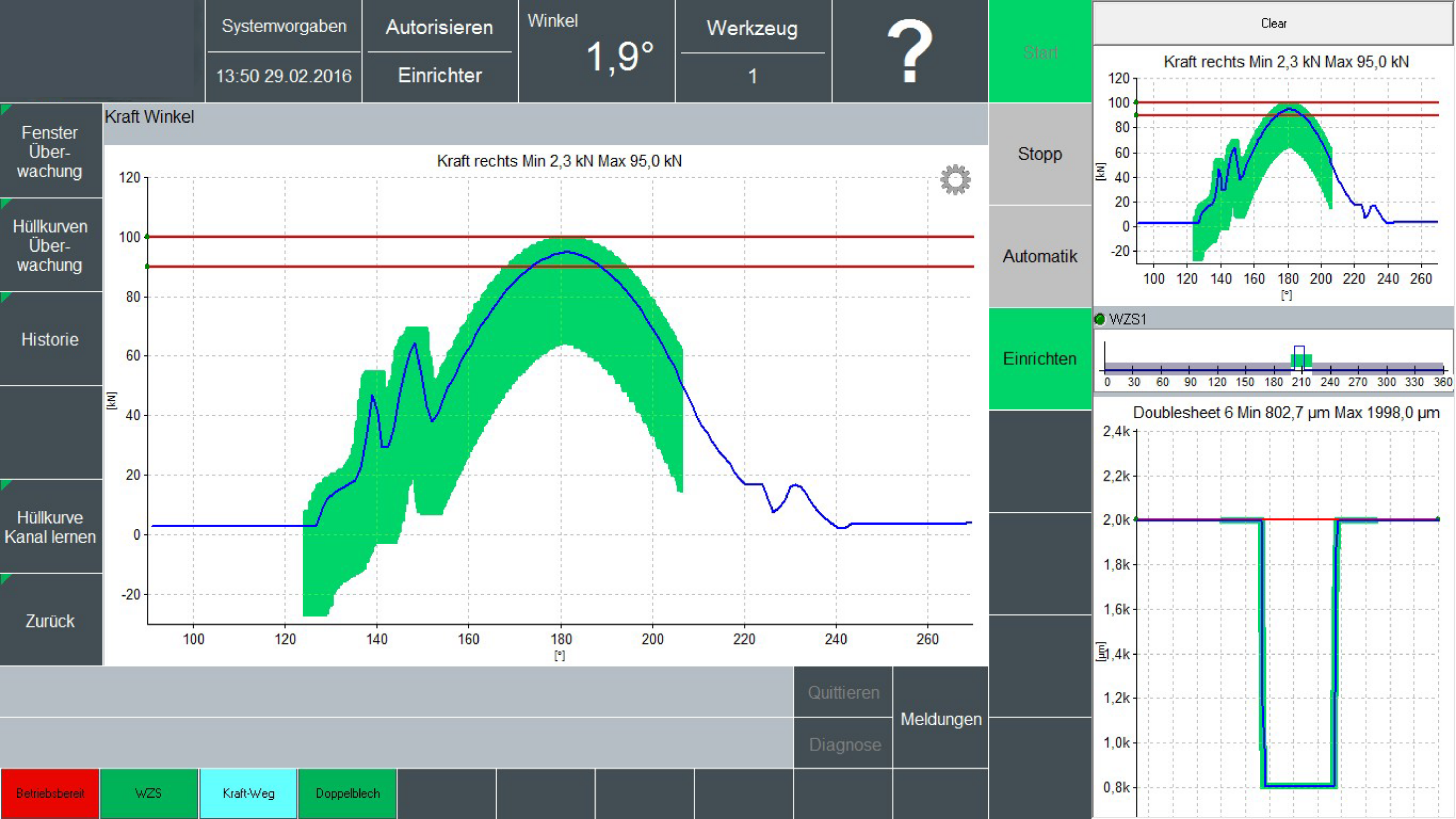

The technology employed involves monitoring tonnage (kn) load/strain on the press frame across multiple channels. Simultaneously, it oversees the status of digital sensors around the tool and the overall process. Complemented by an encoder, our systems provide direct feedback on the machine’s position relative to the applied load, visually represented through a Load vs Angle graph.

This graphical representation allows a comprehensive understanding of tonnage distribution throughout operations such as stamping, drawing, coining, piercing, blanking, and bending.

By setting limits around the full curve, we transcend traditional methods that solely focus on peak loads at the bottom of the stroke.

Our approach monitors load variations across the entire stroke, intervening if deviations fall outside predetermined tolerances. This meticulous oversight not only protects the press from potential issues but also preserves the integrity of the tool.

In the event of an abnormal load—be it over or under—the system triggers an immediate halt, particularly noteworthy in the case of BRUDERER machines, known for their ability to cease processes instantly upon detecting a fault.

Furthermore, our system extends itself to monitoring digital sensors like Fork Probes, Light Grids, Proximities, and Cylinder Positions. All readings are considered in relation to the angle and can be configured for specific counter sequences.

Tailoring our solutions to Traditional Press, High Precision Press, Transfer Lines, Multi-Slide Systems, and various other machines and processes, we invite you to reach out to our technical sales team for any non-standard requirements always open for a challenge.

For those utilising our latest Bruderer controls, our systems seamlessly integrate and feedback to advanced features like dynamic ram height adjustment.

Our monitoring systems are not just a protective measure; they serve as a powerful tool for gaining insights into the forming process and ensuring its stability.

Ultimately, our goal is to empower customers to achieve peak productivity and manufacturing excellence in the realm of pressing and stamping processing.

BRUDERER UK stands as the linchpin for efficient machine, tool, and quality monitoring solutions, particularly in scenarios where millions of parts are produced monthly. Feel free to contact our technical sales team for further information.

Please get in contact with us to for more information about this technology.