Bruderer High Speed Press Doubles Productivity

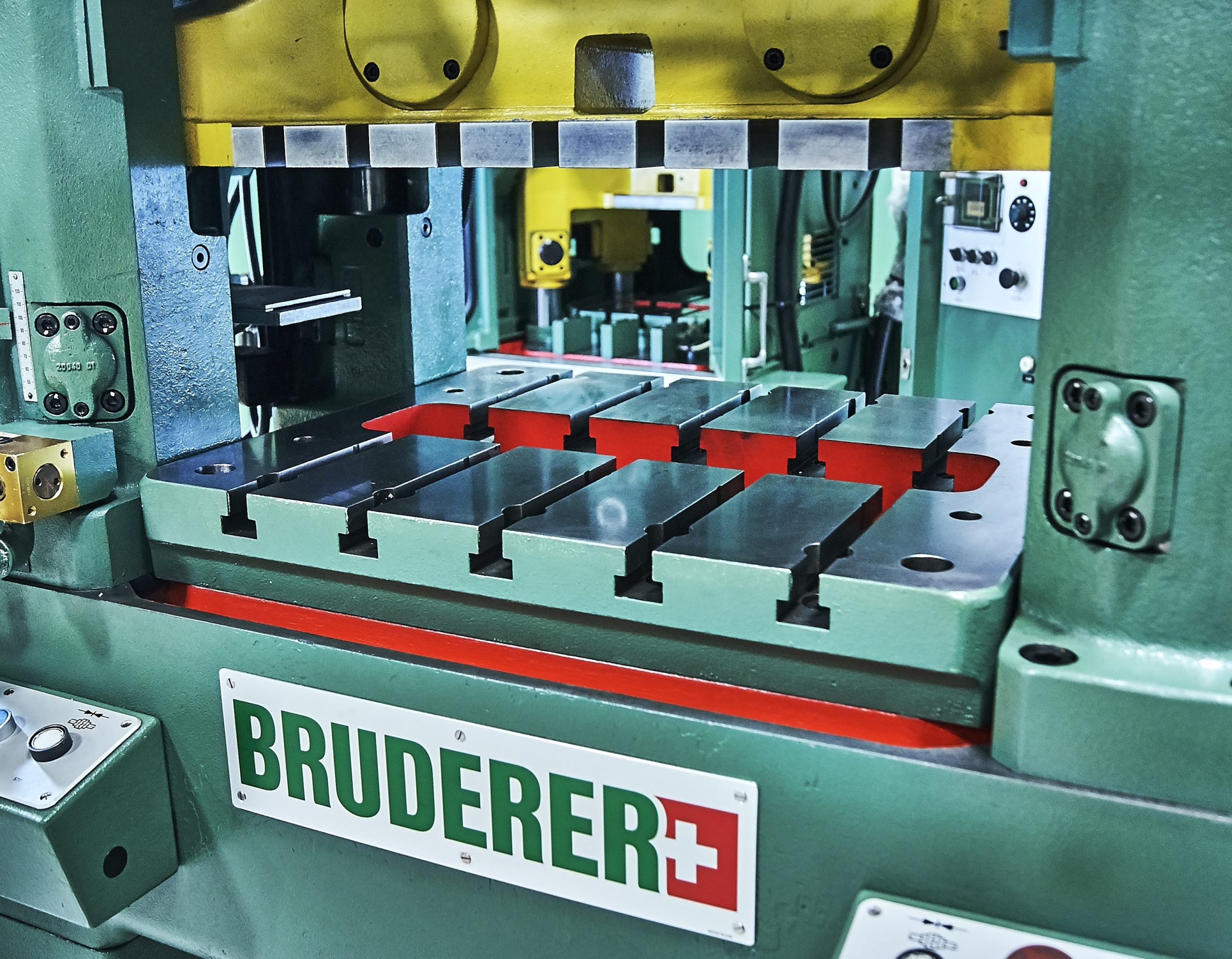

The generous working area and power of a new Bruderer BSTA 510- 125 high-speed press, installed in April 2011 at the Cirencester factory of Batten & Allen, is proving particularly versatile for the precision stamping specialist. The 1,250 mm length of the machine’s bolster plate allows room for two large progression dies to be mounted in-line for manufacturing complex components in one continuous operation. Alternatively, there is sufficient bed width for two tools to be mounted side-by-side and fed with separate coils. In both cases, production output is doubled. Furthermore, punching capacity of 51 tons, which provides sufficient power for two tools to be used simultaneously, also enables heavier pressworking of automotive and other parts if one tool is used, expanding the range of industries that Batten & Allen can serve. Stamping speed is up to 1,050 strokes per minute, slower than the lighter duty presses on site but still an impressive 17.5 hits per second. A 50-ton Bruderer long-bed press, Batten & Allen’s first of that size, was installed at Cirencester in 2006. It has been employed continually for fulfilling a long running contract to make components for the automotive industry. Tools for producing electronic components have been routinely transferred from 30-ton and 50-ton presses on site to the larger machine to utilise its capacity. Batten & Allen has won additional work to produce 50 million jewellery components annually, which surprisingly also requires the larger bed area of a 50-ton press. More recently, two further contracts were awarded for producing fly-by-wire throttle system components destined for motor cycles and golf buggies. These parts also need heavier pressworking capability, so managing director Shawn Batten took the decision to install the BSTA 510-125 to provide additional capacity as well as back-up for the first 50-ton press. However this time, after an in-depth discussion with Bruderer UK’s managing director, Adrian Haller, he opted for a package that is substantially different from the original 50-ton machine. Servo feeds provide extra accuracy and productivity Apart from having slightly higher tonnage, the press is fitted with a bolster plate that is extended by 150 mm to 1,250 mm, providing extra room for a longer progression tool, or two tools in-line. Bolster width is the same at 650 mm and to take advantage of the wide bed, the option of using two tool / die sets side-by-side was created by specifying twin Bruderer BSV75 servo feed units to push two strips up to 75 mm wide through the dies in parallel. Alternatively they will accept one wide strip. Both the upper and lower feed rollers are driven so that pressure is transmitted evenly to the strip. Servo feed technology was not new to Batten & Allen, as it ordered a similar unit with a BSTA 300-85B press bought at the end of 2007. Maintenance manager at Cirencester, Alan Gilbert, commented, "Accuracy of feeding is around plus or minus one thousandth of the pitch length, much the same as for mechanical roll or gripper feeds. "However, the servo gives much more control, as it can be programmed to optimise the timing dynamics on ramp-up, dwell and ramp-down for any given job. "A soft start, for example, will gradually advance the strip for greater feed length accuracy, with or without pilot release, while the facility to control material advance independently of the machine stroke is particularly beneficial if there is a lot of forming, or if parts are delicate. "Moreover, unlike with mechanical feeding, pitch length using a servo is infinitely variable and without limit, and is quickly set at the B-Control system on the press, as is material thickness and all other parameters for the job. The entire program can be saved for immediate reuse next time." Overall, Mr Gilbert said that the first BSV unit has been very reliable and accurate and has led to higher production rates. He also suggests that its ease of use has resulted in a reduction of 10 to 15 minutes in set-up time per job. Mr Batten confirmed that mechanically driven roll feeds are still good for a majority of stamping work. Nevertheless, with the trend towards ever greater accuracy and complexity of parts, underpinned by statistical process control requirements and PPAP (production part approval process) in the automotive sector, servo feed technology is likely to be the norm for future press installations at Batten & Allen. First application for the BSTA 510-125 The first job put on the new Bruderer press did not utilise its twin servo feeds, but exploited the long bed to accommodate two existing tools in series that were previously used on separate 25-ton presses. Designed to produce tin-plated brass components for a telecommunications equipment manufacturer, one tool carries out the blanking while the other completes the subsequent forming. All operations are now performed in one continuous process in the 51-ton press. Mr Batten continued, "This technique results in a substantial saving in unit manufacturing cost, not least through reduced labour content." He added that parallel stamping while feeding two strips through the press will be similarly beneficial, as they can utilise two existing, separate tool / die sets from other presses to provide extra, high productivity stamping capacity for all components. Increasing use of multi-out progression tools also assists in maximising output. Tool monitoring is being fitted to the BSTA 510-125 to check for pitch accuracy and double thickness, as well as a vacuum sensor to detect floating slugs and strip lubrication to promote long tool life. There are currently 24 Swiss-built Bruderer presses on the Cirencester site installed in a temperature controlled, ‘closed-door’ environment, the latter term apparently having meaning for customers in the medical sector. All machines have pallet decoilers and auto recoilers, as production is predominantly automated, reel-to-reel stamping. PC-based control speeds changeover The last seven presses to be installed have been equipped with the Bruderer’s PC-based B-Control system, which facilitates exchanging a full set of modular tools in 20 minutes, three times faster than on earlier machines. As data on each new tool is programmed into the CNC system, it is a simple matter during a repeat run to call up the number of the tool, bolt it onto the press and follow the on-screen prompts to load the program and make the initial and fine adjustments. With a Windows operating system, the CNC system uses easy-to-follow menus on the colour screen and provides process visualisation, press force measurement with tool protection, capacity for 500 records including data not only on the tool but on the order and material as well, and control of up to 10 NC axes. The design of the press itself features a rigid drive shaft mounted transversely, transmitting power to the ram via two con rods, and a lever system with mass counterbalancing for stability at high speeds. Absence of any lateral forces means that the ram guides are at strip level, avoiding punch deflection due to eccentric loads in the die. Accurate tools a necessity In-house design and manufacture of tools at Cirencester is helped by ongoing investment in Agie CNC wire erosion machines to add to the grinders, mills, machining centres and inspection equipment in the toolroom. Accurate tools require the use of top quality pillars and bushes, so Batten & Allen has used Fibro products from Germany since the early 1990s. Also supplied by Bruderer UK, the components are renowned for their quality and precision. Mr Batten continued, “Our customers’ components often stipulate forming tolerances as small as 25 microns. Complex tools are required to hold such tolerances on blanked dimensions, let alone formed features. “By making our tools in-house using Fibro parts to control the relative positions of tool, stripper plate and die to within close limits, we ensure that each set is manufactured to the highest quality. "It is in our own interests not to cut corners, as good tools produce longer runs before they need refurbishing, saving costs and maximising the up-time of the Bruderer presses." At the end of the interview, Messrs Batten and Gilbert agreed that Bruderer equipment has proved very reliable and capable over the years, with some models still working two shifts after 25 years. Support from Bruderer UK was singled out for praise, and so too was the diagnostics package in the B-Control with modem link to the Bruderer factory in Switzerland, which allows software issues to be dealt with immediately. For more information regarding this story, please contact our Luton sales team or visit the Batten & Allen Ltc website at www.batten-allen.com