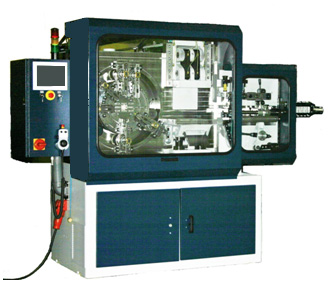

Spotting Presses

Blue line is Millutensil’s first traditional product line. As a matter of fact, Millutensil’s trademark is synonymous around the world with try – out presses, i.e. highly precise machinery created to make it easier to adjust, check and repair moulds which are becoming increasingly more complex. We have supplied hundreds of our blue line products to leading companies in every continent, especially in the automotive sector, where Millutensil has developed a considerable expertise, its stimulus for continuous technical improvement.

Why invest in our SPOTTING PRESSES press?

The fundamental advantages of using our spotting presses are:

- Considerable reduction of mould production costs thanks to time and workforce efficiency optimisation.

- No more dangerous mould handling by means of cranes, forklift trucks or lifting equipment.

- Higher quality dies and moulds with longer service life, attained in less time.

- Testing of extraction pins using the ejector, and movement of the sliding beds using the hydraulic drive of the optional auxiliary cylinders.

- Optional integrated rotary plate for the spotting of multicomponent moulds.

- Considerable reduction of adjustments due to high reproducibility.

- High precision repeatability.

- No more spotting on injection moulding machines, which are cost – intensive and difficult to access.

- Optional integrated rotary plate for the spotting of multicomponent moulds.

- Low operating and maintenance costs.

- Streamlined and safe operation through intuitive controls of the new touch control panel.