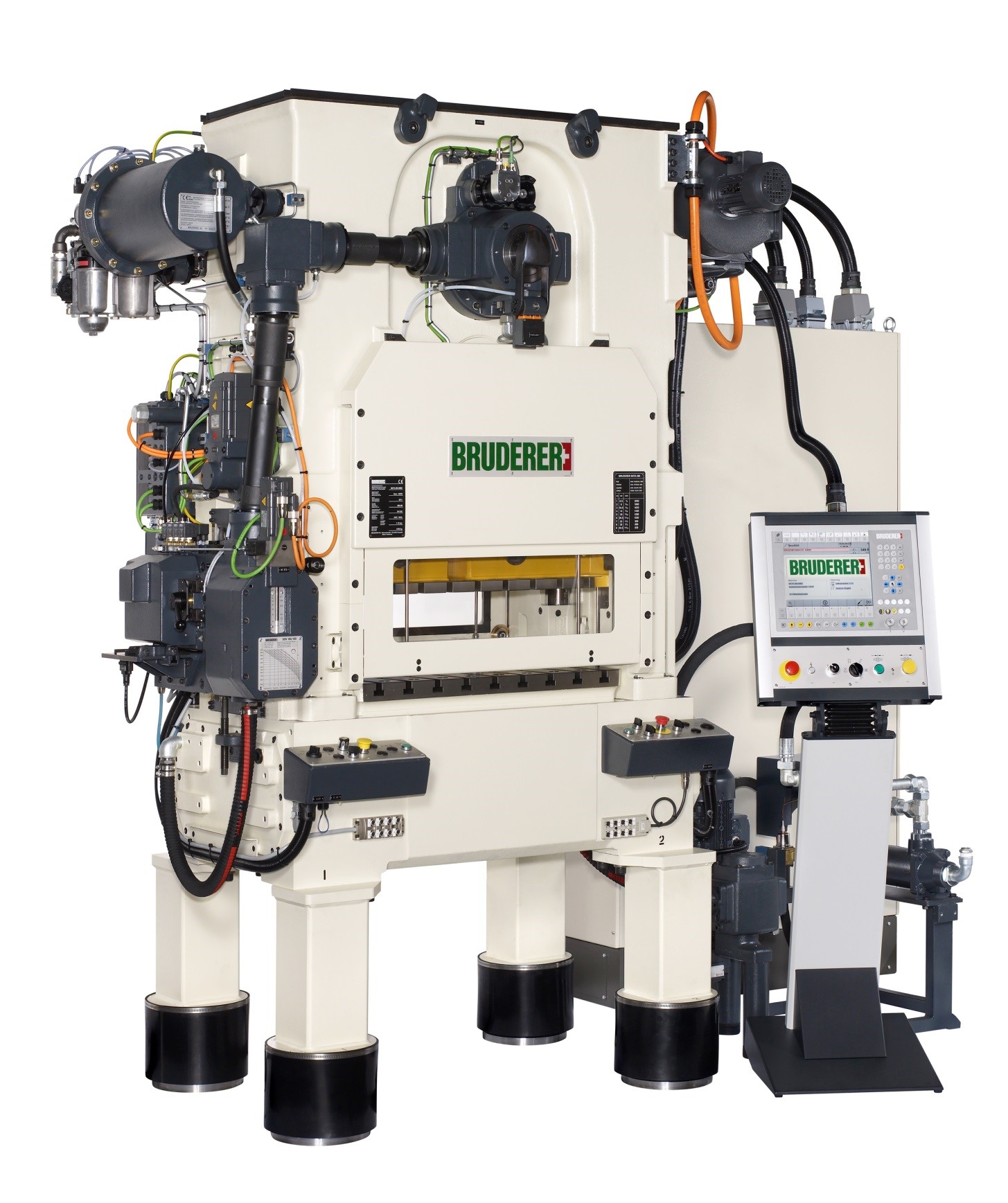

The Power of Servo Feeders

In the world of stamping precision starts with the feed. That’s why Our servo feeders are essential - no matter the power press or industry. Servo feeders are the ultimate solution for precise, consistent material feeding, and they’re compatible with any power press, in any industry. Here’s why they’re a game-changer: Micron-Level Accuracy: Perfectly position material on every stroke....