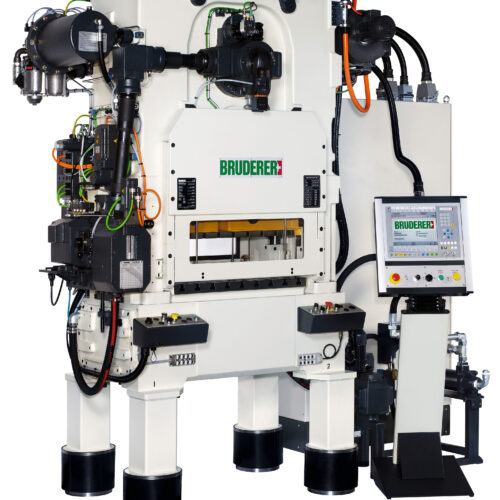

ZUB 100 / 200 (FMS-Q80 RS)

Stamping and bending machine equipped with an AC-servo drive and an intelligent and user-friendly control. Production speed of 25 – 400 pieces/min depending on the tool and component part

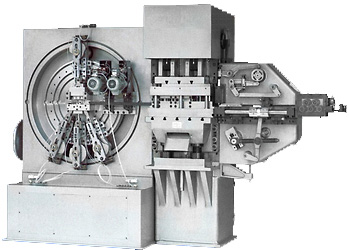

With regard to the size of construction this machine is similar to the Finzer machine ZUB 100 / ZUB 200.

This new machine is equipped with our new control concept by means of which customer-specific automation requirements such as camera tracking, mounting, and assembling can be monitored and managed.

Due to the installed technology a lot of mechanical components such as the service intensive compressed air-brake-combination, the mechanical hand wheel and the big control cabinet have been replaced.

• Precision grip feeder permits a repeat precision of 0.01 mm.

The max. feeding length is 100 mm (special versions up to a length of 200 mm)

• Stamping unit of 80 kN with a stroke of 5/10/12 mm

• Quick-change-plate equipped with up to 11 positively controlled bending slides requiring low maintenance, (bending force of 12/22 kN with a stroke of 44 mm) with a work and a return cam.

Processing of strip material of a width of up to 50 mm and a thickness of 1.5 mm as well as wires of a Ø of up to 4 mm

• Frequency-controlled servo-drive of a power of 4 kW

Concerning the hardware special attention was paid to the following points:

• The supply availability of 20 years can be guaranteed by the in-house developed and produced electronic control unit.

• High operational safety, even at high temperatures and vibrations

• Little space required due to the compact design

• Reduced wiring outlay due to the in-house developed control unit

• Possibilities of automatic and visual diagnosing

• Integrated cam control for controlling internal and external signals

- Reviews (0)

Reviews

There are no reviews yet.